Case Study

Discover some of our past projects and learn about what we can achieve from real cases!

-

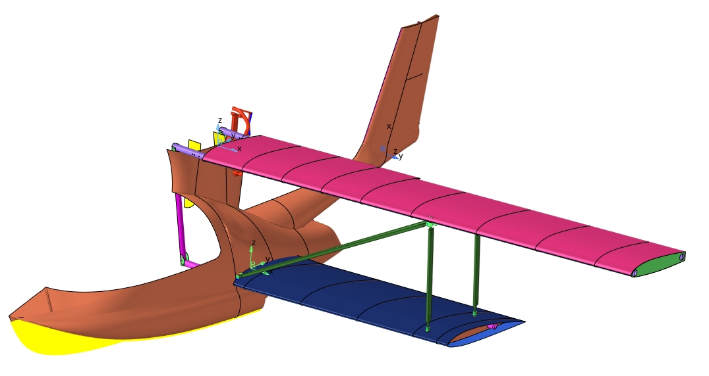

Case Study: Seaplane Structure Design

In the pursuit of innovation, Skoedus collaborated with a leading seaplane manufacturer aiming to optimize their structural design for enhanced performance and efficiency. Utilizing composite materials for reduced mass, the challenge lay in adhering to specific aerospace design rules while achieving design optimization. Skoedus stepped in with a comprehensive numerical simulation approach to address these complexities.

Achievements:

1. Comprehensive Numerical Simulation: Skoedus conducted a fully detailed numerical simulation of the seaplane, applying various loads such as lift and engine forces. This allowed for an in-depth understanding of structural dynamics under different scenarios.

2. Design Optimization: Leveraging Finite Element Analysis (FEA), Skoedus performed design optimization while strictly adhering to aerospace design rules. The simulation results facilitated the identification of optimal design configurations, enabling mass savings without compromising structural integrity.

3. Mass Reduction through Composite Materials: The incorporation of composite materials in the seaplane’s design, guided by simulation results, led to a significant reduction in mass. This not only enhanced the overall efficiency of the seaplane but also met the stringent standards of aerospace design.

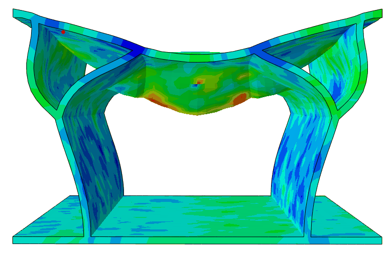

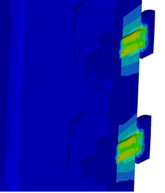

FCAD of the seaplane (half)

FEA result mapping

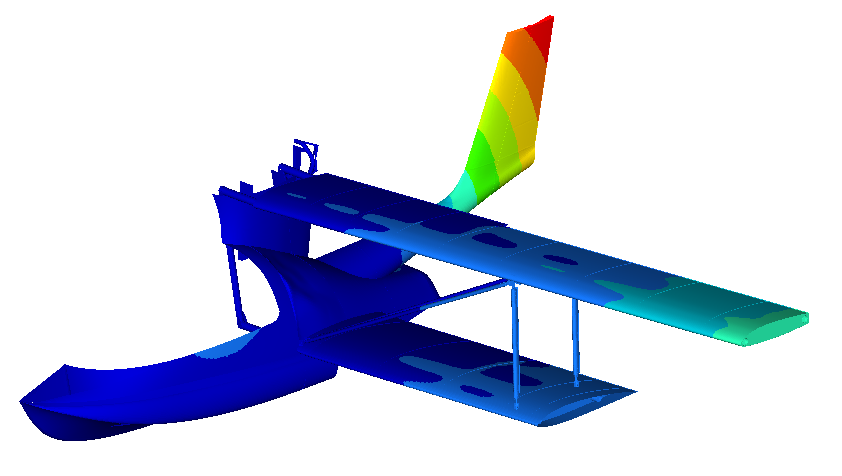

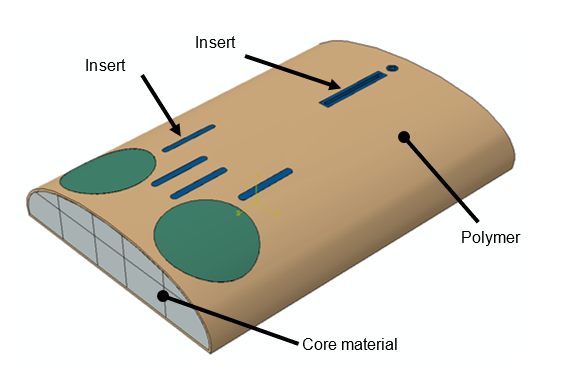

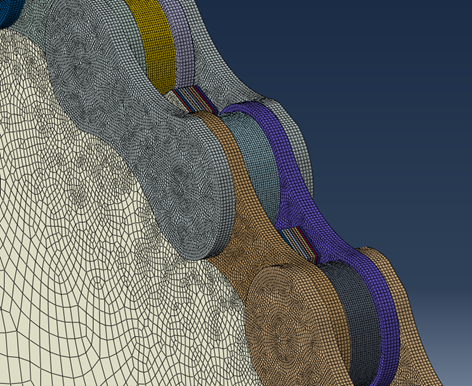

Case Study: Composite Sandwich Insert/Potting Optimization

Skoedus collaborated with aerospace manufacturers specializing in aircraft, helicopters, and drones to optimize the design of sandwich structures. These structures, known for their exceptional strength-to-weight ratio, often involve the assembly of sandwich panels using inserts, including potting. The challenge was to enhance the design of these inserts for improved structural performance, achieved through a combination of numerical simulations and experimental validation.

Achievements:

1. Aerospace Applications Optimization: Skoedus focused on optimizing sandwich structures crucial for aerospace applications, ensuring a balance between strength and weight in aircraft, helicopters, and drones. Reduction of 8% the mass obtained.

2. Numerical Simulation Approach: Using a localized approach, numerical models were developed to simulate the behavior of inserts within the sandwich structure. This approach allowed for a detailed understanding of the structural dynamics at a localized level.

3. Experimental Validation: The numerical models were rigorously compared with experimental results, providing a comprehensive validation process. This ensured that the simulations accurately represented the real-world behavior of the composite sandwich insert.

4. Optimization through Comparison: By comparing simulation results with experimental outcomes, Skoedus identified areas for optimization. This iterative process led to enhanced insert designs, improving overall performance without compromising structural integrity.

Read more:

Mezeix L, Dols S, Bouvet C, Castanié B, Giavarini J-P, Hongkarnjanakul N. Experimental analysis of impact and post-impact behaviour of inserts in Carbon sandwich structures. Journal of Sandwich Structures & Materials. 2019;21(1):135-153. doi:10.1177/1099636216687582

Chalernphonb, Kittigorn, Natthawat Hongkarnjanakul, and Laurent Mezeix. “Numerical Simulation of Residual Strength for Inserts in Sandwich Structures.” Composites: Mechanics, Computations, Applications: An International Journal 11, no. 3 (2020).

doi:10.1615/CompMechComputApplIntJ.2020033858

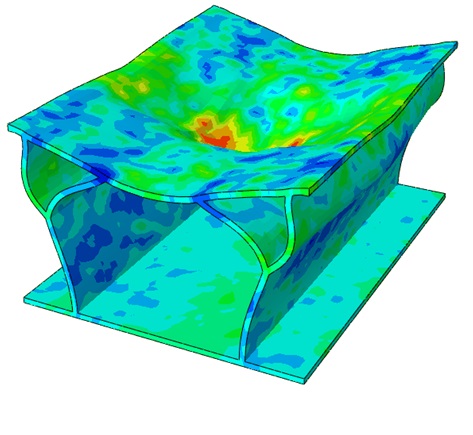

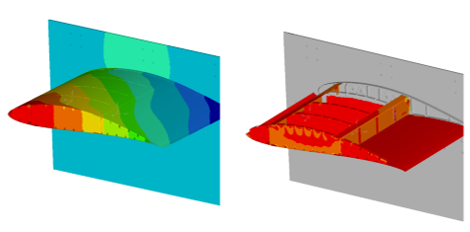

Numerical model of the sandwich and the insert

Overview of pull-through tests

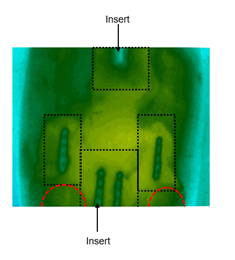

Case Study: Non-Destructive Thermography Simulation for Quality Control Process Optimization

In the sports manufacturing industry, ensuring high-quality products is imperative. However, the complexity of sports equipment structures, which involve composite materials and various inserts, demands an efficient quality control (QC) process. Thermography Non-Destructive Testing (NDT) processes offer a rapid and effective method for QC but can be challenging to calibrate. Skoedus addressed this challenge by utilizing Finite Element Analysis (FEA) simulations to design and optimize the thermography NDT control process. This approach provided optimal parameters, saving time and costs for the company while maintaining stringent quality standards.

Achievements:

1. Sports Industry Quality Control Enhancement: Skoedus focused on enhancing the quality control processes in the sports manufacturing industry, addressing the challenges posed by complex structures and composite materials.

2. FEA Simulation for Thermography NDT Process: Leveraging Finite Element Analysis (FEA) simulations, Skoedus designed and optimized the thermography NDT control process. This approach allowed for the identification of optimal parameters crucial for effective quality control.

3. Efficient Parameter Identification: Through the simulation results, Skoedus identified the best parameters for the thermography NDT process, offering a fast and effective quality control method. This optimization translated to significant time and cost savings for the company.

Read more:

Wongtimnoi, K., Chermprayong, P., & Mezeix, L. (2020). Detection of Bonding Defect in Multimaterials Sandwich Structures Using Thermography and Numerical Simulation Prediction. Composites: Mechanics, Computations, Applications: An International Journal, 11(4).

doi:10.1615/CompMechComputApplIntJ.2020034873

Wongtimnoi, K., Chermprayong, P., & Mezeix, L. (2021). ACTIVE THERMOGRAPHY FOR NONDESTRUCTIVE TESTING OF INSERTS IN MULTIMATERIAL SANDWICH STRUCTURES AND NUMERICAL SIMULATION. Composites: Mechanics, Computations, Applications: An International Journal, 12(3).

doi:10.1615/CompMechComputApplIntJ.2021039136

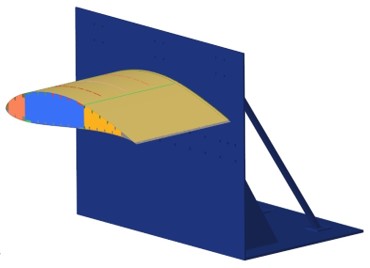

CAD of sport equipment (cross section)

Numerical simulation results and thermography measures

Case Study: Design and Optimization of Non-circular Composite Chainring

In the realm of bike competition and racing, achieving high performance is paramount for success. Skoedus collaborated with elite athletes to design and optimize non-circular chainrings, a critical component for enhancing bike performance. The optimization process involved a meticulous comparison of results from custom mechanical tests, designed internally, and numerical simulations. The validated numerical model then played a crucial role in fine-tuning and optimizing the composite chainring for maximum efficiency.

Achievements:

1. High-Performance Bike Chainring Design: Skoedus collaborated closely with athletes to design non-circular chainrings tailored for high-performance bikes, focusing on achieving optimal efficiency during competition.

2. Custom Mechanical Testing and Numerical Simulation: A custom mechanical testing setup was internally designed for the initial phase of optimization. The results from these tests were then compared with numerical simulations to ensure accuracy and reliability.

3. Validated Numerical Model: Through meticulous comparison and validation, a numerical model was successfully validated using the custom mechanical testing results. This validated model served as the foundation for subsequent optimization steps.

4. Composite Chainring Optimization: Leveraging the validated numerical model, Skoedus optimized the design of the non-circular composite chainring. This optimization process aimed to enhance performance, durability, and overall efficiency during bike competitions.

Read more:

Thanawarothon, Z., Pairat, P., Bouvet, C., & Mezeix, L. (2018). NONCIRCULAR CFRP BICYCLE’S CHAINRING, PART I: STATIC AND LOW-VELOCITY IMPACT ANALYSIS. Composites: Mechanics, Computations, Applications: An International Journal, 9(3).

doi:10.1615/CompMechComputApplIntJ.2018025470

Thanawarothon, Z., Elmikaty, A., Bouvet, C., & Mezeix, L. (2018). NONCIRCULAR CFRP BICYCLE’S CHAINRING, PART II: FINITE ELEMENT ANALYSIS. Composites: Mechanics, Computations, Applications: An International Journal, 9(3).

doi:10.1615/CompMechComputApplIntJ.2018025471

Seller, G., & Mezeix, L. (2019). NONCIRCULAR CFRP BICYCLE’S CHAINRING. PART III: MODELING OF LOW-VELOCITY IMPACT ON TOOTH. Composites: Mechanics, Computations, Applications: An International Journal, 10(4).

doi:10.1615/CompMechComputApplIntJ.2019029738

Non-circular composite chainring

Experiment of the chainring and the chain

Numerical simulation of the chainring

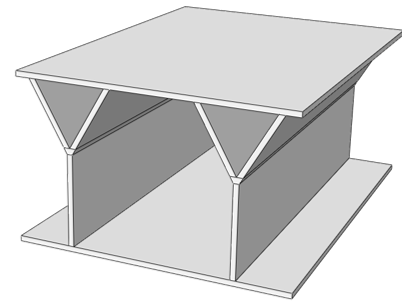

Case Study: FEA Simulation for Blast Impact on Structural Part

In a mission-critical scenario where structural integrity is paramount, Skoedus employed Finite Element Analysis (FEA) to optimize the Y-frame core under blast loading. This case study highlights the explicit simulation, incorporating metallic plasticity properties for realistic blast impact scenarios. Additionally, composites solutions were simulated with damage and failure properties, demonstrating a comprehensive approach to fortifying the Y-frame core against explosive forces. The simulation allowed for a thorough examination of the structural response, providing insights into deformation, stress distribution, and potential failure points.

Achievements:

1. Explicit Blast Impact Simulation: Skoedus implemented explicit simulation techniques to accurately model the Y-frame core’s response under blast loading, considering the intricacies of metallic plasticity.

2. Realistic Material Behavior: Metallic plasticity properties were incorporated into the simulation, providing a realistic representation of the material’s behavior under dynamic blast forces.

3. Comprehensive Composites Solution: Composites solutions were simulated, including the consideration of damage and failure properties. This comprehensive approach allowed for a thorough analysis of structural response in diverse material scenarios.

4. Targeted Optimization for Resilience: Insights from the FEA simulation, considering both metallic and composite materials, were utilized to optimize the Y-frame core for resilience and structural integrity under blast loading conditions.

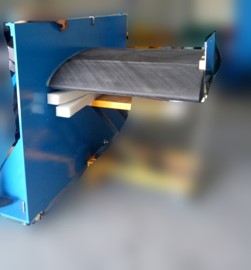

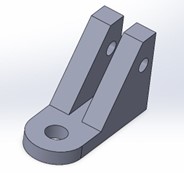

Input part design

Structural part subjected to blast simulation using FEA

Case Study: UAV Wing Section Simulation and Composite Optimization

Objective: Simulation and validation of a UAV wing section mechanical test, followed by the conception of a test bench, prototype design, and composite optimization for a high altitude, high endurance UAV with a 6m wingspan.

Part 1: Test Bench Design and Preliminary Model Design:

- Initiated the process with the design of a test bench and a preliminary model, facilitating the subsequent wing design.

- Preliminary simulations ensured the feasibility of the UAV wing section test, laying the foundation for further development.

Part 2: Conception of Test Bench and Wing Prototype:

- Executed the conception of the test bench and wing prototype, aligning the design with the specific requirements of a high altitude, high endurance UAV with a 6m wingspan.

- Integrated the UAV wing section with the bench, incorporating bolts in a comprehensive assembly simulation to validate the proposed design.

Part 3: Simulation Results and Future Design Usability:

- Successfully simulated the UAV wing section test, providing critical insights into structural behavior for present and future designs.

- The validated model serves as a reliable tool for optimizing future UAV wing designs, ensuring ongoing advancements in aerospace technology.

Design and simulation FEA of wing including complete structure

Part 4: Composite Optimization for Mass Reduction:

- Employed the validated model to optimize the structure of the composite wing design with the primary objective of reducing mass.

- Achieved a remarkable 40% reduction in mass compared to the initial design through innovative composite design following strict aerospace rules.

Achievements:

- Precise Test Bench and Prototype Design:

- The meticulous test bench and prototype design ensured accurate simulation results, laying the groundwork for further optimizations.

- Usable Simulation Model:

- The successfully simulated test model is not only applicable to current designs but also serves as a foundation for the continuous evolution of UAV wing structures.

- Composite Optimization Success:

- The achieved 40% mass reduction demonstrates the success of composite optimization, contributing to the UAV’s overall efficiency and performance.

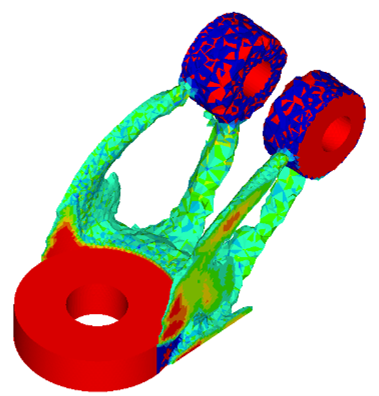

Case Study: Topology Optimization for 3D Printing – Lightweight Metallic Bracket in the Energy Industry

In a recent engineering project focused on the energy industry, our objective was to leverage topology optimization, a cutting-edge computational technique, to design a lightweight and structurally efficient metallic bracket. The primary goal was to exploit the capabilities of 3D printing technology, enabling a significant reduction in mass while maintaining the required structural integrity and performance.

Methodology:

- Topology Optimization: Our methodology centered around topology optimization, a computational approach that iteratively redistributes material within a defined design space. This technique aims to minimize material usage while ensuring the structural efficiency of the component. In this project, the focus was on creating a metallic bracket suitable for 3D printing.

- 3D Printing Integration: The optimized design generated through topology optimization was seamlessly integrated into the 3D printing process. This integration allowed for the creation of complex geometries that would be challenging or impossible to achieve using traditional manufacturing methods.

- Numerical Simulation: Advanced numerical simulations were conducted to validate the structural integrity and performance of the optimized design. This ensured that the bracket met the necessary criteria for functionality and safety within the energy industry.

Results:

- Mass Reduction: The application of topology optimization for 3D printing resulted in a remarkable 67% reduction in the mass of the metallic bracket. This significant reduction in material usage contributes to enhanced resource efficiency and sustainability.

- Structural Integrity: Numerical simulations confirmed that the optimized bracket maintained the required structural integrity and performance standards. This demonstrated the effectiveness of the topology optimization approach in achieving lightweight designs without compromising functionality.

Topology Benefits:

- Resource Efficiency: Topology optimization for 3D printing maximizes resource efficiency by minimizing material usage, contributing to sustainable practices in engineering and manufacturing.

- Complex Geometries: The integration of topology optimization with 3D printing enables the creation of intricate and complex geometries that can enhance the performance and functionality of engineered components.

- Unified Design and Manufacturing: The project showcased the seamless integration of design optimization and manufacturing processes, providing a unified approach for engineers and stakeholders in the energy industry.

- In conclusion, topology optimization for 3D printing offers a transformative solution in engineering design, allowing for the creation of lightweight and efficient components with applications across various industries.

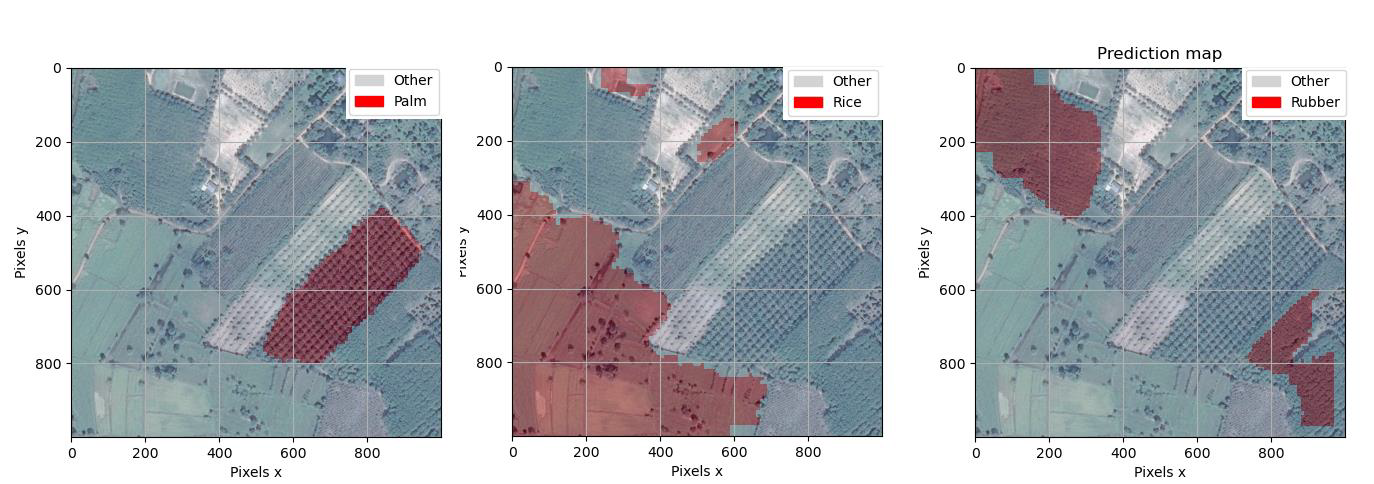

Case Study: Remote Sensing Analysis by AI – Palm, Rubber, and Rice Crops Classification

In a recent project undertaken in Thailand, our objective was to leverage advanced remote sensing analysis, employing state-of-the-art AI techniques. The primary goal was the classification and diagnostic assessment of palm, rubber, and rice crops, contributing to precision agriculture practices in the region.

Methodology:

- NDVI Integration:

- A cornerstone of our methodology involved the incorporation of NDVI (Normalized Difference Vegetation Index), a key spectral index. This allowed for a nuanced evaluation of vegetation health and density, particularly vital in crop classification.

- AI Algorithms:

- Our team implemented sophisticated AI algorithms, trained on extensive datasets, to analyze satellite imagery. These algorithms were tailored for the unique characteristics of palm, rubber, and rice crops, ensuring accurate classification.

- Multi-Step Classification:

- The classification process involved distinct steps for each crop type, considering diverse features such as canopy structure, growth patterns, and spectral signatures. This multi-step approach enhanced the precision of the classification results.

Results:

- Palm Classification:

- Our AI-driven analysis successfully identified and classified palm crops with a high degree of accuracy, providing valuable insights into plantation health and potential yield predictions.

- Rice Classification:

- The AI model exhibited remarkable proficiency in differentiating rice crops, considering factors like flooded fields and growth stages. This classification aids in optimizing irrigation strategies and predicting harvest timelines.

- Rubber Classification:

- Utilizing spectral characteristics unique to rubber plantations, the AI algorithms accurately classified rubber crops. This information is crucial for plantation management and resource allocation.

Satellite images inputs and AI-automated soil identification

Output data: Crop type surfaces

AI Enables:

- Time Saving:

- The integration of AI significantly reduced the time required for comprehensive crop analysis, enabling swift decision-making for farmers and stakeholders in the agricultural supply chain.

- Complete Analysis Through One Tool:

- The seamless integration of remote sensing analysis and AI provided a unified and powerful tool for comprehensive insights. Stakeholders could access a singular platform for a holistic understanding of crop conditions, optimizing resource allocation and decision-making processes.

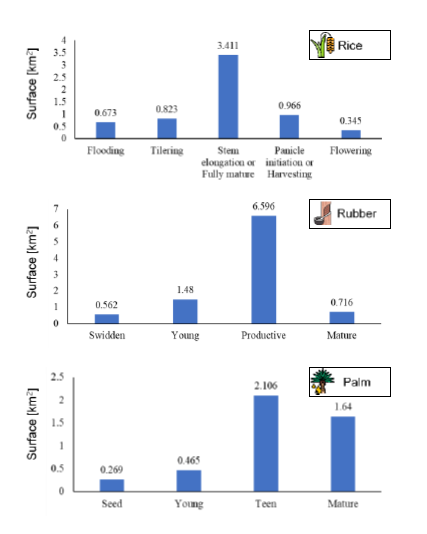

Case Study: In-Depth Analysis of AI-Driven Project: Classification of High Voltage Transmission Poles

In a recent project focused on enhancing safety public regulations, our aim was to implement an innovative AI approach for the classification of high voltage transmission poles. The primary objective was to identify and assess these critical infrastructure elements within satellite images, contributing to improved safety measures and regulatory compliance.

Methodology:

- AI Classification Approach:

- Our methodology involved the implementation of cutting-edge AI algorithms trained to recognize distinctive features of high voltage transmission poles. This process included the analysis of pole structures, heights, and surrounding landscapes for accurate identification.

- Safety Public Regulation Application:

- The project specifically catered to the safety public regulation domain, emphasizing the significance of precise pole classification for regulatory compliance and proactive safety measures.

- Pole Identification by Voltage:

- The AI model was fine-tuned to not only identify transmission poles but also categorize them based on voltage levels. This granular classification enables regulatory authorities to address different safety standards associated with varying voltage capacities.

- Electrical Cable Lines Lengths:

- Beyond pole identification, our AI-driven analysis extended to the measurement of electrical cable lines lengths. This detailed assessment contributes to understanding the spatial layout of the electrical infrastructure, aiding in maintenance planning and system optimization.

Results:

- Pole Identification by Voltage:

- The AI approach successfully identified high voltage transmission poles with a high level of accuracy. Furthermore, the model categorized poles based on voltage specifications, providing a comprehensive overview for regulatory authorities.

- Electrical Cable Lines Lengths:

- The AI analysis yielded precise measurements of electrical cable lines lengths associated with the identified transmission poles. This information is instrumental for utilities and regulatory bodies in planning and maintaining the electrical grid effectively.

Satellite images of high-voltage poles and AI-automated identification results

AI Enables:

- Safety Compliance:

- By utilizing AI for transmission pole classification, regulatory authorities can ensure adherence to safety standards, mitigating potential risks and ensuring the reliability of the electrical infrastructure.

- Proactive Safety Measures:

- The AI-driven identification of poles by voltage enables regulatory bodies to implement targeted safety measures based on the criticality of different voltage levels, enhancing overall system resilience.